IQ series intelligent electric actuator

In the 1990s, ROTORK company in Britain launched smart electric actuator (IQ series), which has the following characteristics compared to ordinary actuators:

(1) Convenient remote parameter setting function. Before into operation, as long as the special setting tool provided by the manufacturer is used to aim at the actuator, the parameter can be set remotely. This not only simplifies the setting procedure but also improves the safety of equipment operation, especially in places where explosion prevention is required;

(2) Rich online display function. Using LCD display technology, can not only accurately display the valve opening and closing status and normal valve opening, etc., but also display important information when setting parameters or when the actuator has a fault;

(3) Perfect self-diagnosis and protection function. It can diagnose online situations such as servo motor overload, overheating, and power supply status, etc, and can also automatically identify the phase of the three-phase power supply. In an emergency, the actuator can maintain its position or run to a pre-set safe position

(4) Advanced control function. Adopting computer technology, it designs advanced automatic following control technology as one of its standard functions. The response speed of the act is proportional to the actual required deviation, which is so-called "speed control", greatly improving the response quality of the actuator;

(5) Strong onsite adaptability. The overall design has the ability of IP54 grade protection, and the ports of the actuator internal and external signals also adopt optical isolation technology, which improves. Especially, the internal control card of the actuator adopts shock-proof fixing method, and all the connectors are equipped with "anti-loosening" to prevent loosening The modular structure makes maintenance very convenient.

【Product Name】IQ Series

【Product Introduction】The electric actuators produced by Rotork company are in the leading position in the field of valve control. The IQ series products are first to use infrared setting without opening the cover for debugging. The reliable double sealing structure can be submerged in water for 3 meters up to 72 hours. The numerous functions make this product a synonym for reliability.

【Main Features】 1. Lifetime of use: No matter what the environment or application, IQ's dual-sealed waterproof housing and protection system provide all-round protection for the internal components.

2. Simple commissioning: Non-invasive infrared setting, convenient and simple, users can set and modify parameters with the press of a button. 3. Dual sealing and dual protection: The protection level is IP68---7 meters underwater for 72 hours, completely waterproof,proof, and airtight.

4. Torque measurement: Patented torque measuring device, advanced technology, not affected by frequency, voltage, and temperature changes, can accurately and measure torque.

5. Position measurement: The patented non-contact valve position measuring system, which accurately determines the valve position and easily determines the end position change of the abality.

6. Remote diagnostics: Using IrDATM to achieve fast, secure, non-invasive communication and data exchange, the actuator data can be analyzed and recommendations be made.

【Basic Functions】 1. Same-step counter: Automatically corrects phase sequence and phase loss protection.

2. Overheat protection: thermal relay inside the motor coil can detect the coil temperature, and when the temperature exceeds the preset value, it can break the control circuit.

3. Valve jam protection: the valve jams, and does not move within 7 seconds after starting, the circuit will automatically break.

4. Instant reverse protection: The automatic delay circuit processes the instant command to prevent impact.

5. Data recording: Each one has a data recorder that can record historical torque, number of times, status, and date, etc., and be inquired, analyzed, and diagnosed in real time.

[Technical Indicators] 1. Local Control

1) A non-intrusive control is provided on the electrical box cover, with the red knob serving as a three-state selector switch for local/stop/remote, and the black knob for local valve opening or electric operation switch.

2) Local control can also be performed within a 0.75-meter range using the IQ setter.

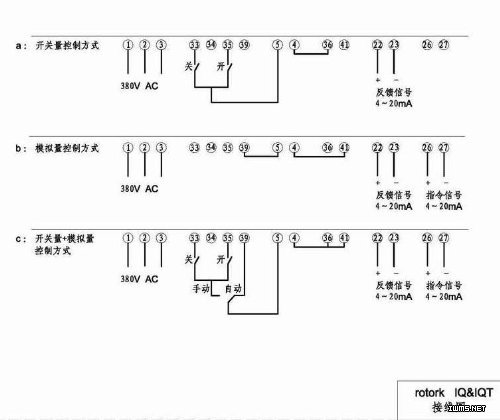

2. Remote Switching

1) An optical isolation interface is used, typically for positive-polarity switching (negative-polarity switching can also be provided).

2) External users provide control: 20-60V AC/DC or 60-120V AC.

3) Control power is provided internally by the actuator: 4V DC.

4) The pull-down power for each control terminal: For 24V DC, it is 5mA; for 120 AC, it is 12mA.

5) The minimum voltage when connected is 20V, and the maximum voltage when disconnected is 3V. The minimum time is 300ms. The maximum capacitance between cores of the cable is: 2uF.

3. Remote Analog Control

1) alternative board - the proportional control board - is added, allowing the user to control with a 4-20mA analog signal.

2) Accuracy: 1%.

3) Dead zone: adjustable from 0-9.9% within the full travel.

4) Input impedance: 250Ω. 5) The input can correspond to the valve position arbitrarily.

4. Output Signals

1) Four passive, single-pole, lockable contacts S1, S2, S3 S4 are provided, each of which can be independently set by the IQ setter to one of the following signals; each contact can be set to "normally open" ornormally closed," with a contact capacity of 5mA-5A 120V AC or 30V DC. a. Valve Position Full open full closed position (accurate) or any intermediate position (0-99% opening). b. Status Valve is opening, closing, running, local stop, local selected, remote selected, open valve or closed valve interlock start, emergency protection start, etc. c. Valve Alarm Motor torque dropout in the travel motor torque dropout in the full open or full closed position, actuator operated by handwheel. d. Actuator Alarm Power phase loss, internal 24V loss, battery voltage too low, temperature protection dropout.

2) A monitoring relay is provided, which is an independent relay that is non-energized and reversible, a contact capacity of 5mA-5A, 120VAC or 30V DC. The relay will open under any of the following conditions or more a. Single-phase or multi-phase power outage b. Control circuit power supply fault c. Selector switch in local or stop position d. Motor temperature relay dropout

5. Analog Signal Output

1) Remote valve position analog display - CPT The current valve position transducer (CPT) provides a -20mA analog signal, with internal power supply and proportional to the valve position, which can be selected to correspond to the valve fully closed or fully open with the minimum signal and automatically set the zero point and full scale. The output impedance is 500Ω, and the repeatability and linearity are within ±1% of the full travel the valve.

2) Remote valve operating torque analog display - CTT The current torque transducer (CTT) provides a non-contact 4-2mA analog signal, with internal power supply and proportional to the output torque of the actuator (0-120% of the rated torque). When the valve is stationary the CTT output will continuously indicate the current torque value.