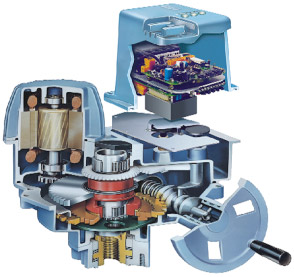

DREHMO electric actuator main components: enclosed motor, eccentric planetary gear mechanism, plugin electrical junction box, handwheel operating mechanism without clutch, combined sensor (torque, stroke measurement), electrical integrated control unit. All planetary gear components are installed around the output and are in constant engagement with several teeth at any time. Unlike traditional spur gears and worm gear structures, it has a compact structure, high mechanical efficiency (70~80) low friction, and a longer service life.

Electric working principle

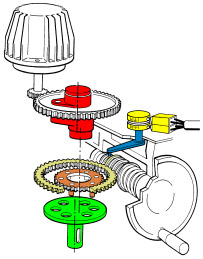

The motor drives the eccentric wheel (3) installed on the output shaft through the transmission group (2), which drives the planetary gear (4) installed on the eccentric wheel. The planetary gear meshes with the internal tooth surface of the sun gear (16. Due to the different number of teeth of the two gears, the motor forms a relative speed when rotating, and the driven shaft (17) fixed on the planetary wheel drives drive disk (5), and the drive disk is in close meshing with the drive hollow output shaft (15), which realizes the opening and closing of the valve.

Manual working principle

When the motor is working, the handwheel remains stationary. When the electric is changed to manual, the electric actuator does not need to on any mechanical conversion device. Under manual conditions, its drive is transmitted to the drive disk (5) and finally drives the output hollow shaft (15) through the offset worm13), sun gear (16) and planetary gear (4).

Over torque protection

The external teeth of the sun gear (16) with the offset worm (13), and the offset worm is fixed in the middle position by a preset loaded spring (12). In the case of torque exceeding preset value of the spring, the change of the circumferential force on the sun gear (4) will cause the offset worm (13) to shift away from the position and start the combined sensor through the torque transmission rod (14).

Stroke position transmission

The output shaft transmission drives the travel transmission gear group installed it to rotate and start the combined sensor.

Working mode

Regulating type electric actuator: Short-time working continuous working time <15 minutes starting and stopping cycle 1200 times/hour. Switching type electric actuator: Short-time working continuous working time <15 minutes, and stopping cycle 600 times/hour.

Long-life eccentric planetary gear transmission mechanism

The unique eccentric planetary gear mechanism is the patented core technology of REHMOThis transmission mechanism is always under multiple forces during operation, which reduces mechanical wear and greatly improves the life of the transmission mechanism. Its mechanical efficiency is 23 times that of the worm gear and worm transmission structure, and it has self-locking function. Permanent lubrication, no need to add lubricant. Egency manual operation The handwheel is always engaged and can operate the drive valve without clutch switching. Convenient and practical to reduce failure points. When electric, the hand is always in a static state, and even if the handwheel is operated, it will not bring any negative effects. A dedicated connection can be provided for operation, and the valve be quickly driven by electric tools.

EMG enclosed electric

Use a fully enclosed high torque, low inertia squirrel cage encapsulated motor, and has moisture dustproof performance, which ensures that it can operate reliably in harsh environments. Insulation grade: F class.

Motor overheat protection

Using three series ofheat development embedded in the motor coil, when the motor test exceeds 155℃, the control circuit is interrupted and the machine is stopped

Three series-connected overheating relays are embedded in the motor windings, and when the motor test exceeds 15℃, the control circuit is interrupted and the machine is stopped. Combined sensor The displacement of the output shaft and the actual torque value are converted into corresponding signals by Hall effect (permanent magnetic pole), using absolute value encoding. It has the following features:

-No need for a backup battery, and the changing can be recorded during a power outage.

-Non-contact, no friction, long life.

-Extremely high precision and repeatability of position and torque.

Ambient temperature

Standard model: -25℃ to 70℃

Explosion-proof model: -20℃ to 40

Sealed protection grade

According to IEC144, EN60529 and DIN VDE0470 standards, it is supplied with a protection grade of IP67, and IP68 products can also be provided according to customer requirements.

Painting and anti-corrosion measures

Standard paint: RAL5015 blue

Outdoor installation: anti-corrosion protection K3 grade

Corrosive environment: anti-rosion protection K4 grade, housing sealed protection grade IP68.

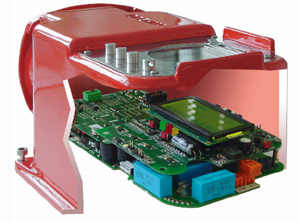

Integrated control unit

It is equipped with a main control board, positioning board (), motor starter, and space heater. In extreme high or low temperature environments, we recommend using the body product. Local control unit

It can achieve local operation and switching between local remote main operation.

It can be adjusted without opening the cover.

It can be locked to prevent misoperation.

Dual-al structure

When the terminal box is folded down on site for on-site wiring, the integrated control unit is still isolated from the outside world. This structure protects the components from the effects of the external environment and improves the reliability of the entire machine.

Electrical junction box

It contains compact pluggable terminal blocks, which are to control signal lines and power cables, respectively. After the initial installation wiring is completed, you will never have to worry about folding the wiring again