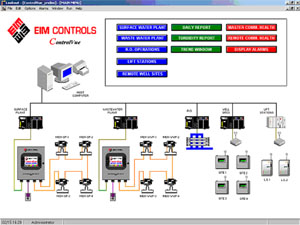

EIM offers a full line of rotary actuators for quarter-turn and multi-turn applications The torque range is from 50 to 334,000 Nm with operating times from 5 seconds to 12 minutes or more, for the of ball, plug, butterfly and damper gates, etc.; multi-turn actuators with torque range from 50 to 13,560 N and thrusts up to 114,000 Kgf, for the operation of gate, globe, check, and multi-turn dampers, etc. IM pioneered the introduction of digital control products and networks for the valve industry in 1985 with the introduction of Controlinc®. It is a two-wire digital system specially designed by EIM for valve control and was first certified to Modbus, Foundation Fieldbus, etc. Controlinc® is capable of supporting over 0 network protocols including Modbus RTU, Modbus Plus, Foundation Fieldbus, Profibus, DeviceNet, Ethernet, Lonworks, ASI, etc. It the qualification for mutual recognition with all major DCS and SCADA control systems world-wide. EIM has extensive experience and a proven track record in the digital control products and systems and is in a position to offer a total solution for the automatic control of the actuator portion. The first actuator produced by EIM was installed in 199 on an oil pipeline in Saudi Arabia. It is still offering safe and reliable service today - even with temperatures of 170F (77°C) on the conveying temperature. No matter how severe the working environment, you will find EIM. EIM has a record of over 3000 electric actuators in a contract and we have supplied thousands of electric actuators to Exxon-Mobil alone. In a Los Angeles water plant, EIM actuators are reliably switching heavy gate valves; EIM actuators installed on a Canadian tunnel crossing have withstood years of -40F. From Kuwait and Saudi Arabia pipeline to Mobil tank farm in; from JINGDAL steel in India to British Petroleum's FORTIES-C offshore platform; from BEAR power plant in the USA to Qinshan nuclear plant in China; EIM has diligently supplied high-quality control and excellent service. To date over two million EIM actuators have been serving users under various environments andatic conditions all around the world, setting a precedent for lasting, reliable operation. EIM Company has been pre-eminent! Today, EIM Company, as a professional manufacturer actuators, has not ventured into any unrelated fields. From basic products to fully intelligent products with part turn and multi-turn capabilities, our products have the ability to perform total process control.

EIM Product Standards

① NEC National Electrical Code

② NEMA National Electrical Manufacturers Association

③IEEE Institute of Electrical and Electronics

④ ANSI American National Standards Institute

⑤ UL Underwriters Laboratories

⑥ AWWA C540/93 American Water Works Association

⑦OD-V-24657 (SH)

Reasons for choosing EIM:

① Extensive experience with a variety of valves and dampers.

② Rigorous industrial-grade standards.

③ All components made in the USA.

④ Detailed specifications, dimensions, technical data, and performance history provided for engineering evaluation.

⑤ Standard (8.5"×11" A) size drawings.

⑥ Detailed and accurate product specifications, bill of materials, and circuit diagrams for sales reference and final.

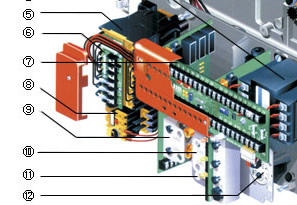

⑦ Adequate and complete electrical and mechanical components.

⑧ Prompt delivery.

Additional benefits for users:

① Safe and easy-to- standard limit and torque switches.

② High-performance industrial-grade motors.

③ Simple conversion for adjusting speed and torque output.